Elevating Aerospace Engineering with Precision Tooling Solutions and collaborations.

NIKKEN’s Involvement within the Aerospace Industry

As a leading provider of advanced tooling solutions, NIKKEN are playing a critical role in the manufacturing processes of some of the world's most advanced aerospace components.

NIKKEN’s solutions includes high-precision CNC rotary tables, tool holders, and other advanced machining technologies that are essential in the production of complex aerospace parts and ensuring that every component meets the rigorous standards required for aircraft performance and safety.

NIKKEN's tooling solutions are designed to meet these exacting requirements, offering unparalleled accuracy, reliability, and efficiency. By partnering with leading aerospace manufacturers across Europe, NIKKEN Kosakusho Europe has contributed to the production of components for commercial airliners, military aircraft, and space exploration vehicles.

NIKKEN’s Aerospace Collaborations and Innovations

NIKKEN Kosakusho Europe has established strong partnerships with major aerospace companies and suppliers. These collaborations have led to the development of specialised tooling solutions tailored to the unique needs of the aerospace sector. By working closely with these industry leaders, NIKKEN has been able to innovate continuously, ensuring that their tools not only meet but exceed the demands of modern aerospace engineering.

An example of NIKKEN’s tool holders that are designed specifically for the aerospace industry is the X-Treme Milling Chuck. NIKKEN's exclusive X-TREME Chuck and cutting tool shank was developed to meet the requirements of a major aerospace manufacturer to improve manufacturing times, reduce costs and improve the reliability associated with machining titanium jet engine fan hubs. Offering: optimum gripping, patented shank retention system, allows the X-Treme Chuck to be used in the manufacture of all sizes of components across numerous sectors. With its innovative convertible sealing system, providing either fully sealed cooling through the cutting tool or jet cooling to the outside of the cutting flutes, the X-Treme Chuck is able to meet the demands of difficult to machine and exotic materials used throughout the aerospace industry.

For the customer concerned the ultimate benefit from introducing X-TREME, as well as total process confidence, was a drastic reduction in both cycle time and tooling costs (over 50%)!

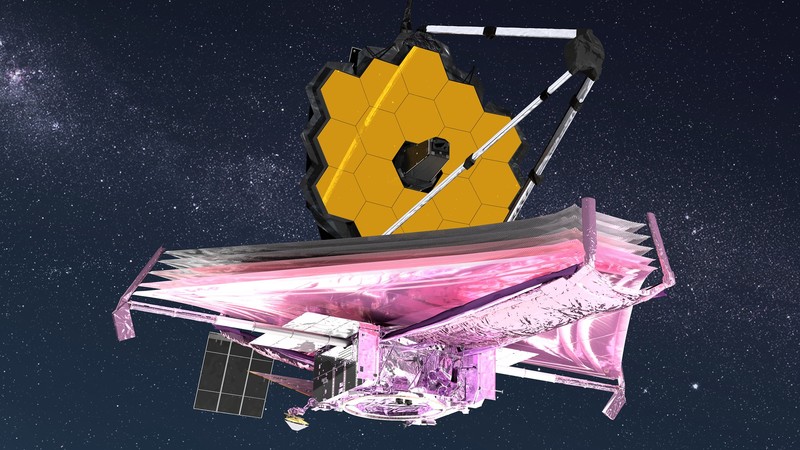

Furthermore, NIKKEN are delighted to be a part of the manufacturing process behind James Webb's telescope with NIKKEN's world-leading multi-lock, being used to help manufacture the 18 hexagonal segments, which all align to focus light and act as one giant mirror.

The Multi-Lock Milling Chuck offers an incredible 80-85% taper contact, better than AT3 standard, offering the spindle guarantee, increasing accuracy and reducing the spindle motor load and ultimately consuming less energy and energy, improving sustainability. Thus, proving the perfect tool holder to produce such a large and intricate piece of equipment.

Looking to the future…

As the aerospace industry continues to evolve, with increasing emphasis on sustainability and efficiency, and NIKKEN’s work in the aerospace industry is a testament to their dedication to quality and innovation. By providing the tools that enable the creation of cutting-edge aerospace technology, NIKKEN is helping to shape the future of aerospace.