Key differences and benefits between a 4th and 5th Axis Rotary Table.

FAQ: What are the key differences and benefits between a 4th and 5th Axis Rotary Table?

The main difference between 4th axis and 5th axis machining lies in the number of rotational axes they employ, which affects the complexity and capabilities of the machining process.

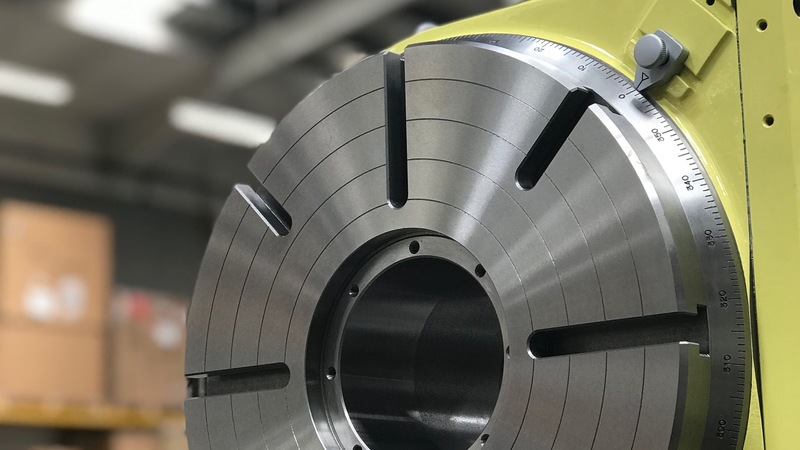

4th axis machining uses three linear axes (X, Y, Z) plus one rotational axis. It typically rotates the workpiece around a single axis, often parallel to X or Y. This setup allows for machining on four sides of a part without repositioning. 4th axis machining is particularly suitable for parts with features evenly spaced around a central axis. It is less complex and generally more affordable than 5-axis machining.

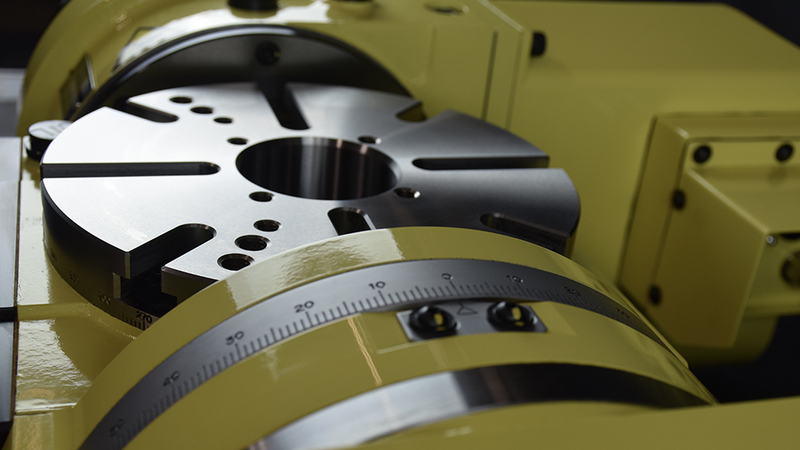

In contrast, 5th axis machining uses three linear axes (X, Y, Z) plus two rotational axes. This configuration can rotate the workpiece or the cutting tool in multiple directions, allowing for machining complex geometries and reaching difficult angles. 5th axis machining is capable of producing parts with undercuts and intricate shapes. It reduces the need for multiple setups, thereby improving accuracy and efficiency. While more versatile, 5th axis machining is also more complex and expensive than 4-axis machining.