NIKKEN’s Involvement within the Oil and Gas Industry

At NIKKEN we take pride in being a global leader in precision engineering, and our commitment to quality and innovation has established us as a leading solution provider to manufacturers within the oil and gas industry.

For over 65 years, NIKKEN products and machine tool accessories have been used to enhance the precision and efficiency of manufacturing processes across various sectors. With our expertise in precision tooling systems, CNC rotary tables, and machine tool optimisation NIKKEN have played a critical role in meeting the demanding requirements of the oil and gas industry.

Precision Tooling: Delivering Quality for Critical Operations

The oil and gas industry operates in some of the most challenging environments, where equipment must endure extreme conditions and meet the highest safety and quality standards. NIKKEN's precision tooling solutions, including our industry-leading range of NC Tooling, single or twin axis CNC tables and tool presetters, are all engineered to support the production of top-quality components for oilfield equipment, pipelines, and drilling tools. The products we provide are not only designed to meet the manufacturing demands and processes of parts and components designed to fulfil the temperature constraints, high pressures and demanding environments, common in the industry, but also to ensure that our customers can rely on their equipment for reliable, safe and efficient operations.

NIKKEN precision tooling products deliver unmatched accuracy, stability, durability and longevity. By minimizing machining errors, we help our customers reduce waste and increase tool life. This results in significant cost savings and improved reliability for oilfield operations, reinforcing our role as a trusted partner in the industry.

Rotary Tables: Enabling Complex and Flexible Machining

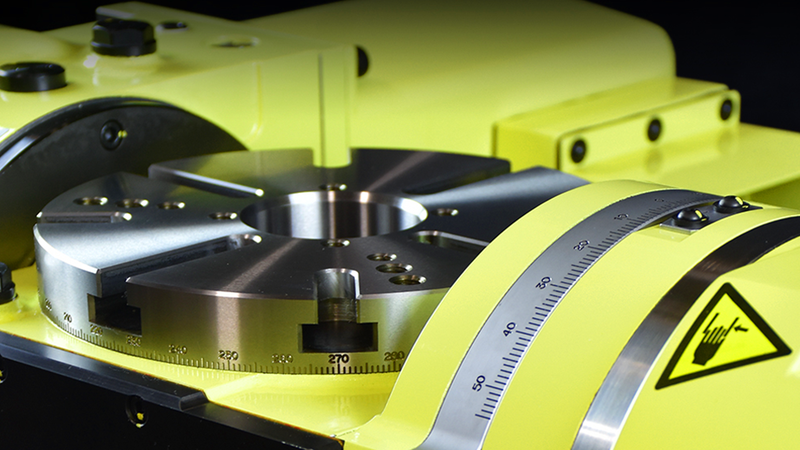

Our CNC rotary tables are essential to the oil and gas sector, enabling multi-axis machining that allows for the creation of complex components with ease, precision and exceptional accuracy with 5 Axis machines ranging from sizes 100mm up to 1200mm.

The integration of rotary tables in CNC machining helps our customers achieve higher productivity by reducing the need for multiple setups and promoting more automated processes. This capability ensures that manufacturers in the oil and gas industry can meet their production timelines without compromising the quality required for equipment that performs in harsh operating conditions.

Supporting Downstream and Upstream Operations

NIKKEN’s technologies support various stages of the oil and gas value chain, including upstream exploration, and downstream processing. High Value Manufacturers to the Upstream and Downstream Oil and Gas Industry trust NIKKEN products when producing precision components for use in arduous applications. Where millions of dollars are potentially at risk from process interruptions it is not worth trusting the integrity of finished products to anyone other than NIKKEN.

NIKKEN have worked with a plethora of businesses within the industry, including Global giants in steel production and engineering, Sheffield Forgemasters. Discover more about how Forgemasters improved gripping force and a consistent accuracy of concentricity of the cutting tool within 5 microns using NIKKEN Tool holders and Alberti Angle Heads below.