The Process behind NIKKEN's Refurbished Rotary Tables

With a dedicated team of specialist service engineers, we ensure all refurbished NIKKEN Rotary Tables are built to the highest standard.

Using parts from our extensive warehouse stock of around 1 million, our experienced team perform full strip downs and mechanical rebuilds, reinstating the Rotary Table to near original condition and performance.

The process of refurbishing a NIKKEN Rotary Table starts as any other service or repair, by carrying out an extensive functionality check. This gives the team a good idea of the initial condition of the table before any refurbishment work is carried out.

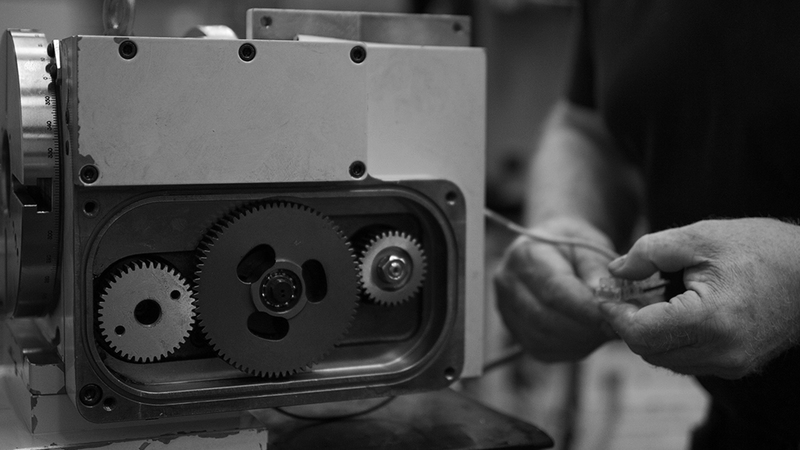

The second stage in the process is completely stripping the table down and performing a deep cleaning of all component parts. This allows our engineers to carry out further inspections and identify what parts require replacement. The castings covers and all external faces are then sent off for full degreasing and powder coating. Once these have been powder coated, the rebuilding process then begins.

All the bearings, seals, o-rings, gaskets, oil sight glasses, oils and greases are replaced as standard with all refurbished Rotary Tables. Other components such as the worm screw, worm gear and brake components are also replaced if necessary, ensuring ultimate performance.

Once the rebuilding process is complete, the table then goes through another series of vast functionality and alignment checks using our in house CMM, this is to ensure that the finished product is as close to original condition and performance as possible.

EXTENDED WARRANTY

To give you peace of mind, all of our refurbished rotary tables now come with the same 12-month standard warranty as all of our new rotary tables.

EX-DEMO AND REFURBISHED ROTARY TABLES OFFERS

(PDF - 293 KB)

LEARN MORE ABOUT OUR RANGE OF REFURBISHED TABLES