What is Tool Management?

FAQ: What is Tool Management and what are the benefits of it.

What is Tool Management?

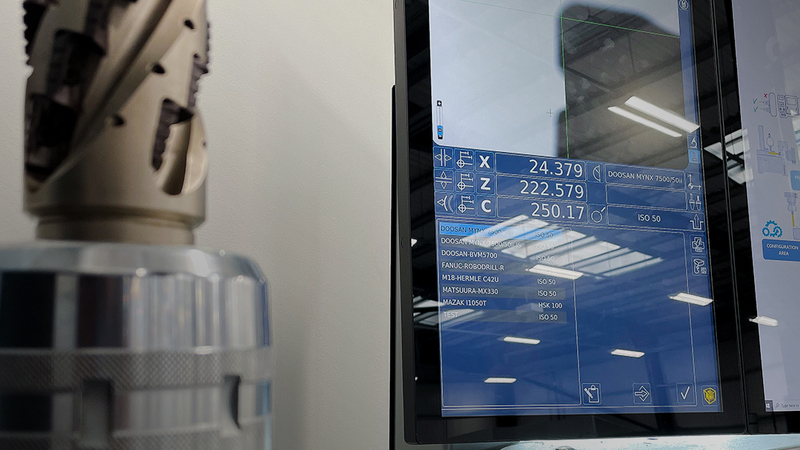

Tool Management is a connected system that provides up-to-date and real-time information regarding the status of tooling assemblies, consumables, durables, and all associated data. Information such as stock locations, minimum stock levels, costs, components used in Tool Assemblies, cutting parameters, and Assemblies used for each Job are made available in a centralised location to provide the consolidated information required to make informed, efficient business decisions.

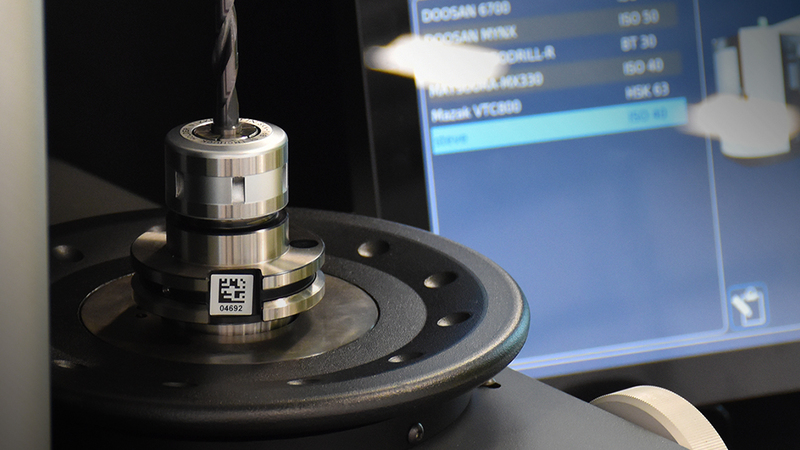

Using NIKKEN’s TP32 Tool Management system, it is possible to manage and track the entire lifecycle and value chain of all tooling related data, including integration with many common vending systems, CAD/CAM packages, and ERP systems to provide end-to-end transfer of data and reduce time taken for duplicate data entry or creation of 3D models, for example.

TP32 aims to streamline the Tool Management process and ensure an efficient workshop where the tools needed for each machine are ready, just as they are needed.

What benefits can Tool Management add to my business?

Tool Management provides direct efficiency, cost, and risk reduction, and reliability benefits to manufacturing organisations.

Without such a system, risks include but are not limited to:

- Inventory duplication resulting in unnecessary overspend e.g. limited visibility of stock levels in real-time, whether durables are in use or an actual purchasing requirement.

- Potential for machine downtime while awaiting inventory that is actually unavailable or in-use,

- Reactive procurement rather than proactive based on upcoming jobs and production demands,

- Incorrect loading of tool geometries and tool data to the machine tool, resulting in non-conformance components and machine spindle collisions with downtime costs.

Our TP32 digital package helps to eliminate such downtime and risks, improves efficiencies and reduces costs. Some of the benefits are as follows:

- Stock visibility to engineers, procurement, and tool room, reducing the risk of overordering,

- Stock consolidation and bulk purchasing power by providing engineers with improved visibility,

- Understock reporting, ensuring key items are always kept in stock,

- Visibility to tool room of tool assemblies required per job, helping to ensure all tools are ready when required at the machine,

- Tooling measurements and tolerances with digital assembly sheets, minimising risk of picking, assembly, and measurement errors,

- Reduced risk of scrap, rework, and machine/fixture damage due to incorrect offsets,

- Version control of production jobs,

- Clear job costing based per tool,

- Transferring CAD / CAM data between packages, reducing multiple data entry and potential mistakes.