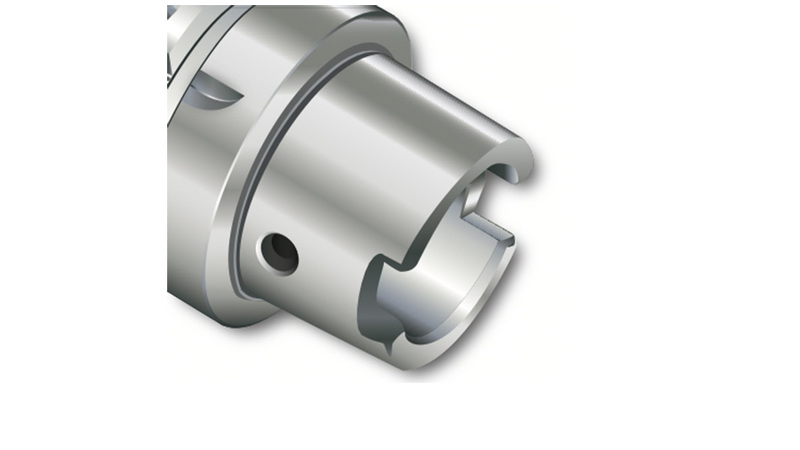

Micro VC Holder Collet Chuck

NEW Micro VC Holder:

NIKKEN’s NEW Micro VC Holder, available in both monobloc for compact high-speed spindles and straight shank variants, is an innovative solution designed to enhance machining processes for the latest generation micro machine tools and spindles where increased spindle speeds and balanced tool holding is are necessity.

Available in both straight (MVH) and tapered (MVHT) body configurations the NEW MVH tool holder range is optimised for high-speed HSK spindles and, by providing supreme accuracy and reliability from NIKKEN’s 8-degree collet, perfectly lends itself to the parts and processes normally applied to this type of compact platform. Smaller, highly detailed and often expensive components can demand superior precision, optimum clearance and ultimate access - exactly what our new range was designed for and where MVH excels!

NEW HSK-E - Symmetrical Shank

The new Micro VC Holder is predominantly designed around the HSK-E symmetrical tool holder shank. Unlike more common HSK-A systems the flange form and shape is designed and optimised for high-speed rotation and is therefore fully symmetrical with no drive slots, tooling hole or timing notch. This provides superior balance and also reduced vibration at higher rotation speeds – hence it has become the common connection choice for such machine tools and tool holding.

HSK-A

HSK-E

-

Run-Out : 3μm at 4×Diameter

-

High speed : MAX. 50,000rpm

-

8° taper collets : Superior Gripping

-

Quick and easy loading

NEW Straight Shank Micro VC Holder:

Indeed, with the inclusion to the range of our versatile MVH straight shank extension we provide users more effective use of standard-length cutting tools. Available in two diameters this additional choice negates the need for costly over length cutting tools, when an extended reach is required, which can result in significant cost savings and increased reliability for intricate processes. By accommodating more standard cutting tools, in conjunction with a suitable collet chuck, the straight shank MVH solution simplifies operations, reduces cutting tool inventory, lowers costs, and minimizes machining complexity.

| Capacity 'D' | Code | Length 'L' | Nut/Nose Dia. 'C' | Shank Size | |

|---|---|---|---|---|---|

| HSK20E-MVH4-33 | 3.0-4.0 | MVH4 | 33 | 12 | HSK20E |

| HSK20E-MVH6-35 | 3.0-6.0 | MVH6 | 35 | 14 | HSK20E |

| HSK25E-MVH4-45 | 3.0-4.0 | MVH4 | 45 | 12 | HSK25E |

| HSK25E-MVH6-45 | 3.0-6.0 | MVH6 | 45 | 14 | HSK25E |

| HSK25E-MVHT4-45 | 3.0-4.0 | MVHT4 | 45 | 12 | HSK32E |

| HSK25E-MVHT6-45 | 3.0-6.0 | MVHT6 | 45 | 14 | HSK32E |

| HSK32E-MVHT4-45 | 3.0-4.0 | MVHT4 | 45 | 12 | HSK32E |

| HSK32E-MVHT4-60 | 3.0-4.0 | MVHT4 | 60 | 12 | HSK32E |

| HSK32E-MVHT6-45 | 3.0-6.0 | MVHT6 | 45 | 14 | HSK32E |

| HSK32E-MVHT6-60 | 3.0-6.0 | MVHT6 | 60 | 14 | HSK32E |

| HSK40E-MVH4-45 | 3.0-4.0 | MVH4 | 45 | 12 | HSK40E |

| HSK40E-MVHT4-60 | 3.0-4.0 | MVHT4 | 60 | 12 | HSK40E |

| HSK40E-MVHT6-60 | 3.0-6.0 | MVHT6 | 60 | 14 | HSK40E |

| HSK50E-MVH4-50 | 3.0-4.0 | MVH4 | 50 | 12 | HSK50E |

| HSK50E-MVH6-55 | 3.0-6.0 | MVH6 | 55 | 14 | HSK50E |

| HSK50E-MVHT4-80 | 3.0-4.0 | MVHT4 | 80 | 12 | HSK50E |

| HSK50E-MVHT6-80 | 3.0-6.0 | MVHT6 | 80 | 14 | HSK50E |

| S12-MVH4-130 | 3.0-4.0 | MVH4 | 130 | 12 | 12mm |

| S13-MVH6-160 | 3.0-6.0 | MVH6 | 160 | 14 | 13mm |